Nationwide delivery network service utilising our own fleet of vehicles.

From our headquarters near the port of Hull, we have excellent access to sustainable timber imports from Europe and wider international markets.

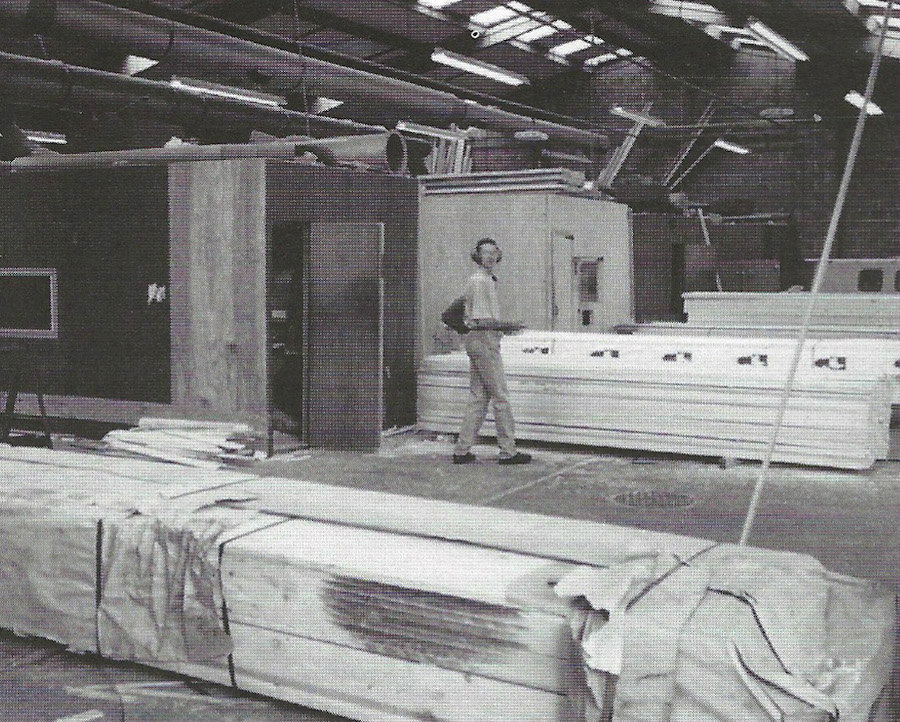

And with more than 80,000sqm of storage space available, we can quickly process and distribute high-quality timber, softwood-based products and panel products anywhere in the UK & Ireland.